EZE-CRACK® PVC Crack Inducer System

PRODUCT BROCHURE

Press X Arrow Toggle for Full Screen View

Product Description

CORKJOINT® Eze-Crack® PVC Crack Inducer System is a two-part rigid PVC Crack Inducer System used in concrete ground slabs and concrete pavements to induce controlled cracks at pre-determined locations while allowing for continuous concrete pouring. Eze-Crack® PVC is made from high quality rigid PVC and is installed into position during pouring of the concrete but after the levelling/screeding of the concrete has been placed and while the concrete is still wet, finished flush with the top of the surface.

As the concrete cures and shrinkage takes place, Eze-Crack® PVC will induce a crack downwards in a controlled fashion, helping to eliminate uncontrollable surface cracking of the concrete ground slab or concrete pavement. Position placement of Eze-Crack® PVC must be determined/advised by the Project’s

Design Engineer, so to achieve the best desired joint location for the concrete ground slab or concrete pavement.

Advantages

- Fast and easy to install.

- Induces cracks in concrete without having to saw cut joints.

- A two-part system with removable top section for ease of joint sealant application.

- Available in different heights to accommodate specific concrete slab thickness.

Provides controlled and accurate cracking of the concrete, eliminating random

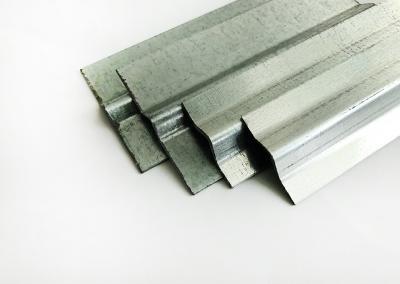

cracking. - Produced from high quality rigid PVC in convenient long lengths of 5 metres. Custom lengths also available to suit your project’s requirement.

Note: The product’s size (height) design, performance, its intended use, installation, final confirmation and approval for use, must be provided by the project’s Design Engineer and Project Manager.

Areas of Application

Designed for use in concrete:

- Ground Slabs and Pavements.

- Warehouse & Industrial Factory Floors.

- Airport Runways & Taxiways.

- Highways , Freeways & Bridges.

- Transport Depots.

- Shipyards & Wharves.

- Footpaths & Walkways.

Technical Features

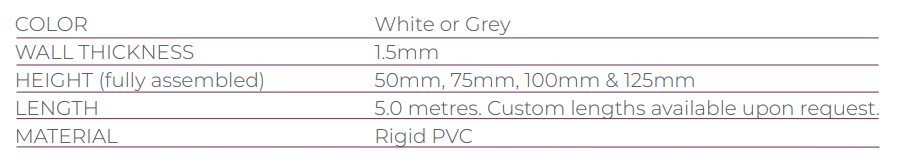

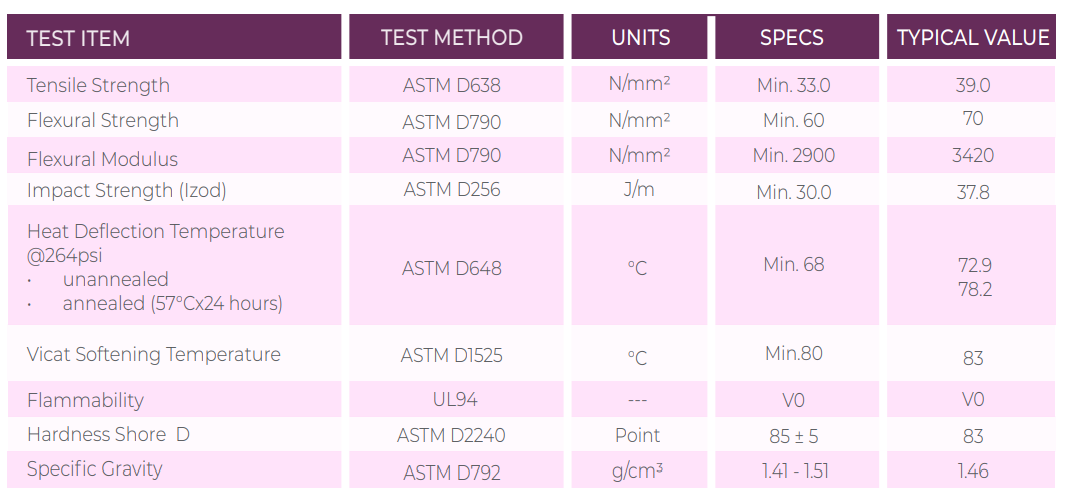

Physical Properties

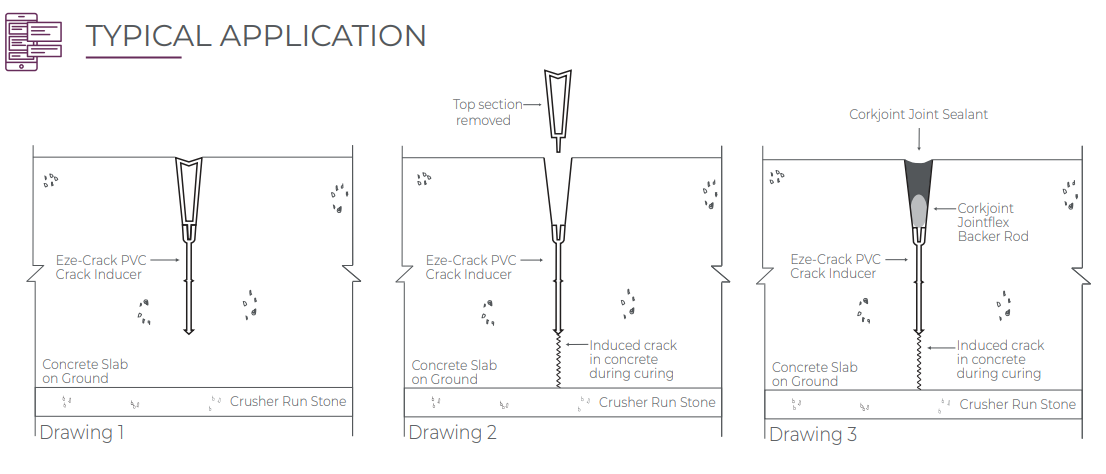

Typical Application

Refer to the Product Brochure for diagram.

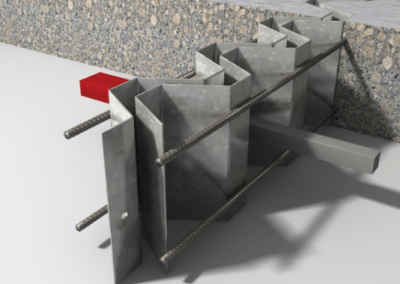

D1: Eze-Crack® PVC inserted into wet concrete, flush with the surface.

D2: Removal of top section after concrete has cured and when joint sealant is ready to apply.

D3: Application of CORKJOINT® Joint Sealant and Jointflex Backer Rod into joint void.

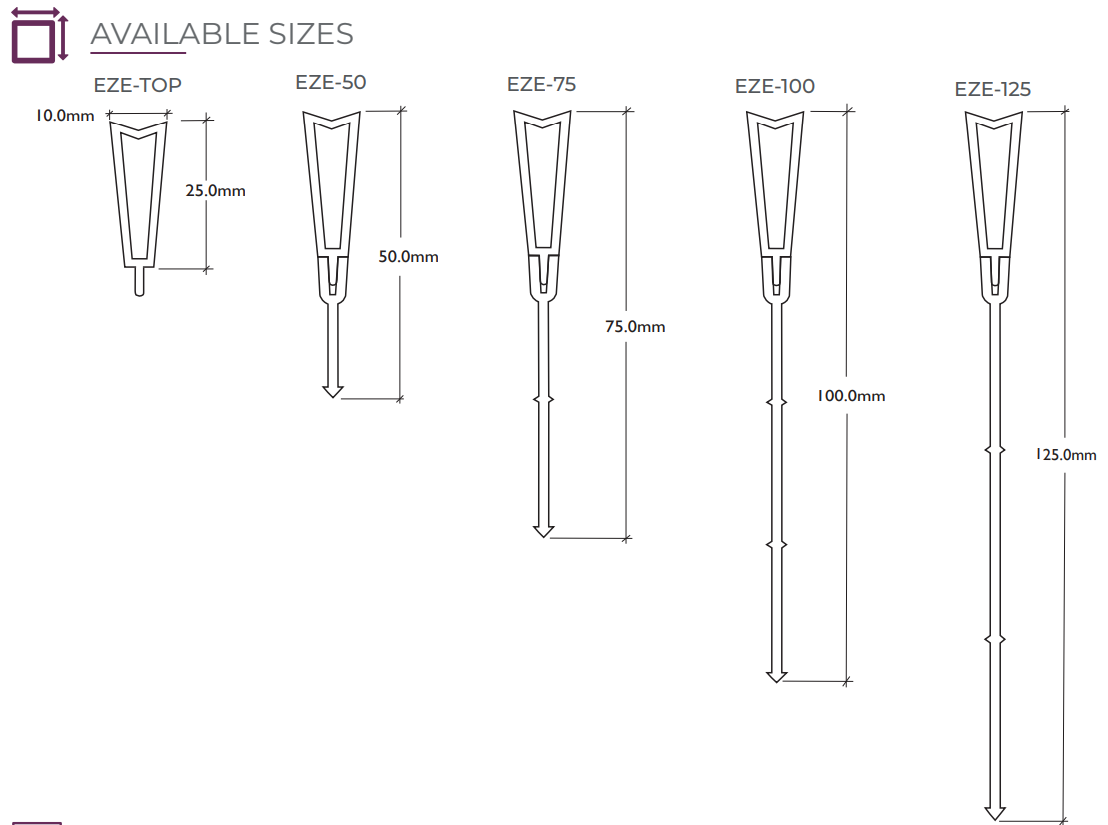

Available Sizes

Determination of Size (Height) to Use

As an indication or rule of thumb, the height of the selected Crack Inducer should be approximately 1/3rd or 1/4 of the overall slab thickness. Induced crack is impacted by concrete strength and reinforcement sizes and configurations.

Note : The product’s size (height), design, performance, its intended use, installation, final confirmation, and approval for use, must be provided by the project’s Design Engineer and Project Manager.

Installation Procudures

- With the use of a marker pen, mark the pre-determined position of the joint location for the concrete slab or pavement, on the top of the outside formwork on each side.

- During concrete screeding/levelling, and while the concrete is still wet, place a string line on the mark placed on the formwork and ‘flick’ the string line to leave a slight imprint into the top of the wet concrete.

- While the concrete is still wet, insert an aluminium or metal T-section into the concrete to form a groove into the concrete for easy insertion of the Eze- crack® PVC.

- Remove the T-section and insert the Eze-Crack® PVC vertically into the groove. With a series of gentle push and pull movements from left to right in the longitudinal direction of the Eze-Crack® PVC, the product will slowly immerse itself into the concrete, and finish it flush with the top of the concrete surface.

- Once the concrete is fully cured, and when the Joint Sealant is ready to be applied, remove the top section of the Eze-Crack® PVC, starting from one end and slowly lifting upwards.

- Thoroughly clean out the joint void before inserting and applying CORKJOINT® Jointflex Backer Rod and applicable CORKJOINT® Joint Sealant. Refer to CORKJOINT® for applicable Joint Sealant for the specific project’s requirement.

Note : Eze-Crack® PVC should not be placed after full screeding has taken place but when screeding has only just passed the location and in arms reach of where the Eze-Crack® PVC is to be inserted.

Written Specification

Where shown in the drawings, the concrete Crack Inducer shall be Eze-Crack® PVC Crack Inducer System as supplied by CORKJOINT®. The application and installation of the product must be in accordance with the manufacturer’s/supplier’s suggestions as stated inside the product brochure or the technical data sheet.

Health & Safety Information

For further information or advice on health and safety precautions, safe handling, storage and correct disposal of products, please refer to the most recent product Safety Data Sheet (SDS), which is available upon request.

Product Brochure Validity

CORKJOINT® undertakes modifications to its product brochures on a continual basis, as and when required. Please check under the product summary section at www.corkjoint.com to ensure that you have the latest version of our product brochures.

Disclaimer

The information and the recommendations relating to the application and end use of this product are given in good faith and are based on the information provided by the manufacturer of the product and/or the Company’s current knowledge and experience in connection with the product when properly stored, handled and applied under normal conditions and no liability of final function at the job site is assumed. In practice,

the differences in materials, substrates and actual site conditions are such that no warranty in respect of merchantability of, or fitness for, particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written and/or oral recommendations, or from any other advice offered by the Company. The Company also has no express or implied knowledge of any particular purpose for which the product is required and any such information given will not be taken into account in the supply of this product. No responsibility or liability by the Company will be accepted for misuse, misreading or derivation from recommended guidelines in respect of this product and the user shall determine the suitability of the product for his intended use and assume all risks and liability in connection therewith. The information contained in our brochure may change at any time without notice. Any use of this product, Eze-Crack® PVC, in any application should be approved as suitable for use/application by the Design Engineer and Project Manager.