Superseal CR Chemical Resistant Butyl Waterstop Seal

PRODUCT BROCHURE

Press X Arrow Toggle for Full Screen View

Product Description

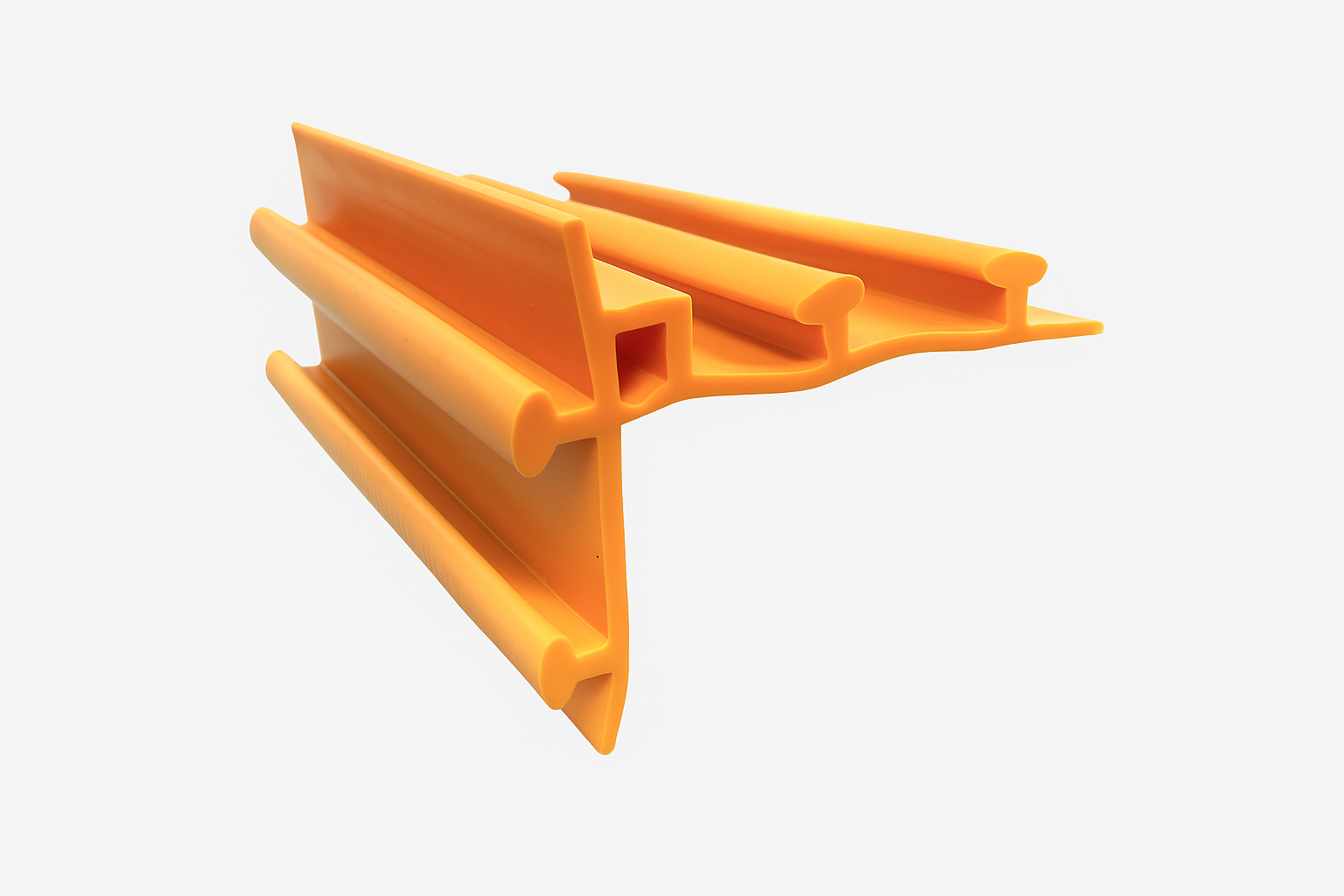

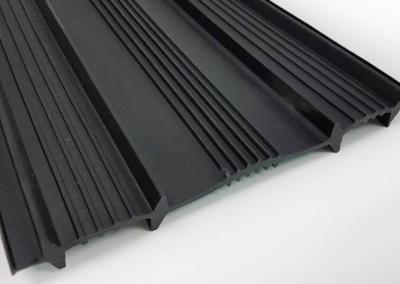

CORKJOINT® SUPERSEAL CR Chemical Resistant Butyl Waterstop Seal is a specially formulated chemical & hydrocarbon resistant butyl waterstop seal for use in construction joints (non-moving joints) where a permanent flexible watertight seal is required.

SuperSeal CR’s unique sealing compound acts as a sealing gasket to seal joints in concrete against the egress of liquids.

SuperSealCR is ideal for use in horizontal and vertical construction joints for cast in-situ concrete structures.

Advantages

- Fuel & Oil Resistant Waterstop Seal (refer to Chemical Resistance Data on Page 2).

- Excellent adhesion and conformation to the joint surface.

- Provides a permanent, flexible gasket seal inside the concrete joint.

- Bonds to most types of surfaces including concrete, fiberglass, metal, plastic and

aluminium. (Refer to CORKJOINT®’s Installation Parameters) - Able to resist rain/wet conditions prior to the 2nd pour taking place.

- Sealed joints will not shrink, harden or oxide upon ageing.

- Low to high temperature workability: -7°C to +48°C Rugged service temperature: -34°C to +93°C

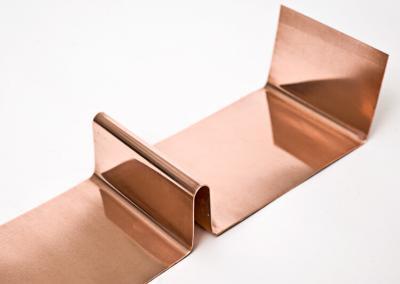

- Can be used in conjunction with other waterstop systems as added benefit/protection to the

structure and to the system. Consult CORKJOINT® for their product recommendations and suitability.

Areas of Application

For all types of Construction Joints in concrete or Non-Moving Joints in pre-cast elements where a chemical & hydrocarbon resistant waterstop seal is required. Refer to CORKJOINT® for application suitability.

- Petrochemical Plants

- Chemical Plants

- Fuel Storage Containment

- Refineries

- Vehicle Depots & Maintenance Yards

- Pharmaceutical Plants

- Waste Water Treatment Plants

- Sewage Treatment Plants

Note : The product’s design and performance, its intended use, installation and final confirmation and approval for use, must be provided by the project’s Design Engineer and Project Manager.

Design Parameters

- Superseal CR must be installed in construction joints (non-moving joints) only. It cannot be used in

expansion or isolation joints (moving joints). - Superseal CR must be installed to CORKJOINT®’s recommended Installation Parameters as stated

below. - Superseal CR can be used in conjunction with other waterstop systems as added benefit / protection to the structure and to the other system. Consult CORKJOINT® for product suitability.

Note : The product’s design and performance, its intended use, installation and final confirmation and approval for use, must be provided by the project’s Design Engineer and Project Manager.

Typical Installations

Superseal CR requires a minimum 50mm cover of concrete from the outside edge.

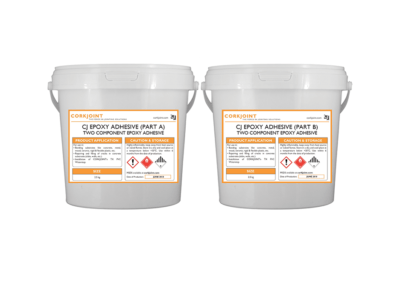

- Brush off any dust or debris from the surface where the Superseal CR is to be applied. Brush a coat of Superseal CR Adhesive 30mm wide onto the concrete surface and one coat to the surface of the Superseal CR.

- Once both surfaces where the adhesive was applied are touch dry, with the use of your thumbs or heel of your hand, firmly press a continuous bead of Superseal CR into position, making sure you achieve full contact with the adhesive on the concrete surface. Do not stretch the Superseal CR-400 when applying it into position.

- Use a neat, firm butt joint to join Superseal CR together and then knead the ends together to form a continuous uninterrupted gasket. This type of join is used for continuous placement of Superseal CR and for any intersection joints.

- Check to see that the Superseal CR has totally adhered to the concrete surface. If the surface is rough or irregular, you may need to use a firmer hand pressure to make sure that the Superseal CR has full contact with the surface. There must be no visible gaps under the Superseal CR after installation.

- The protective paper layer cover on the Superseal CR can be removed any time prior to the second pour of concrete taking place.

- Placement of the second pour of concrete can be applied once the Superseal CR Adhesive has dried. Upon pouring, make sure the concrete is properly compacted and vibrated around the Superseal CR.

- For vertical construction joints and overhead applications, it may be necessary to also secure the Superseal CR with nails, placed approximately every 250mm apart. This is usually only required as extra security if you need to pour your concrete prior to the Superseal CR Adhesive drying completely.

Refer to the Product Brochure for more details.

Packaging and Dimensions

- Superseal CR – 25mm x 19mm x 5m rolls (6 rolls per carton)

- CJ-100 Adhesive – 1 litre tin & 3.6 litre tin

- CJ-100 Adhesive coverage (approx.) – 20 – 30m per 1 litre

Written Specification

Chemical resistant waterstop seal shall be Superseal CR as supplied by CORKJOINT® with dimensions, shape and material properties as illustrated/mentioned in their brochure. All installation and joining procedures must be in accordance to CORKJOINT®’s recommendations and requirements.

Health and Safety Information

In confined spaces or in still air conditions, the use of a ventilation fan or suitable respirator should be used, and the advice and approval of the site Safety Supervisor is essential. For further information or advice on health and safety precautions, safe handling, storage and correct disposal of products, please refer to the most recent product Safety Data Sheet (SDS), which is available upon request.

Product Brochure Validity

CORKJOINT undertakes modifications to its product brochures on a continual basis, as and when required. Please check under the product summary section at www.corkjoint.com to ensure that you have the latest version of our product brochures.

Disclaimer

The information and the recommendations relating to the application and end use of this product are given in good faith and are based on the information provided by the manufacturer of the product and/or the Company’s current knowledge and experience in connection with the product when properly stored, handled and applied under normal conditions and no liability of final function at the job site is assumed. In practice, the differences in materials, substrates and actual site conditions are such that no warranty in respect of merchantability of, or fitness for, particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written and/or oral recommendations, or from any other advice offered by the Company. The Company also has no express or implied knowledge of any particular purpose for which the product is required and any such information given will not be taken into account in the supply of this product. No responsibility or liability by the Company will be accepted for misuse, misreading or derivation from recommended guidelines in respect of this product and the user shall determine the suitability of the product for his intended use and assume all risks and liability in connection therewith. The information contained in our brochure may change at any time without notice. Any use of this product, Superseal CR, in any application should be approved as suitable for use/application by the Design Engineer and Project Manager.