SURE-SHIELD® TPER Chemical Resistant Waterstop

Click on Image to view full screen

PRODUCT BROCHURE

Press X Arrow Toggle for Full Screen View

Product Description

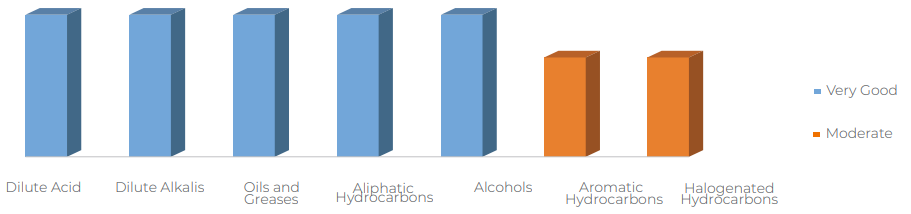

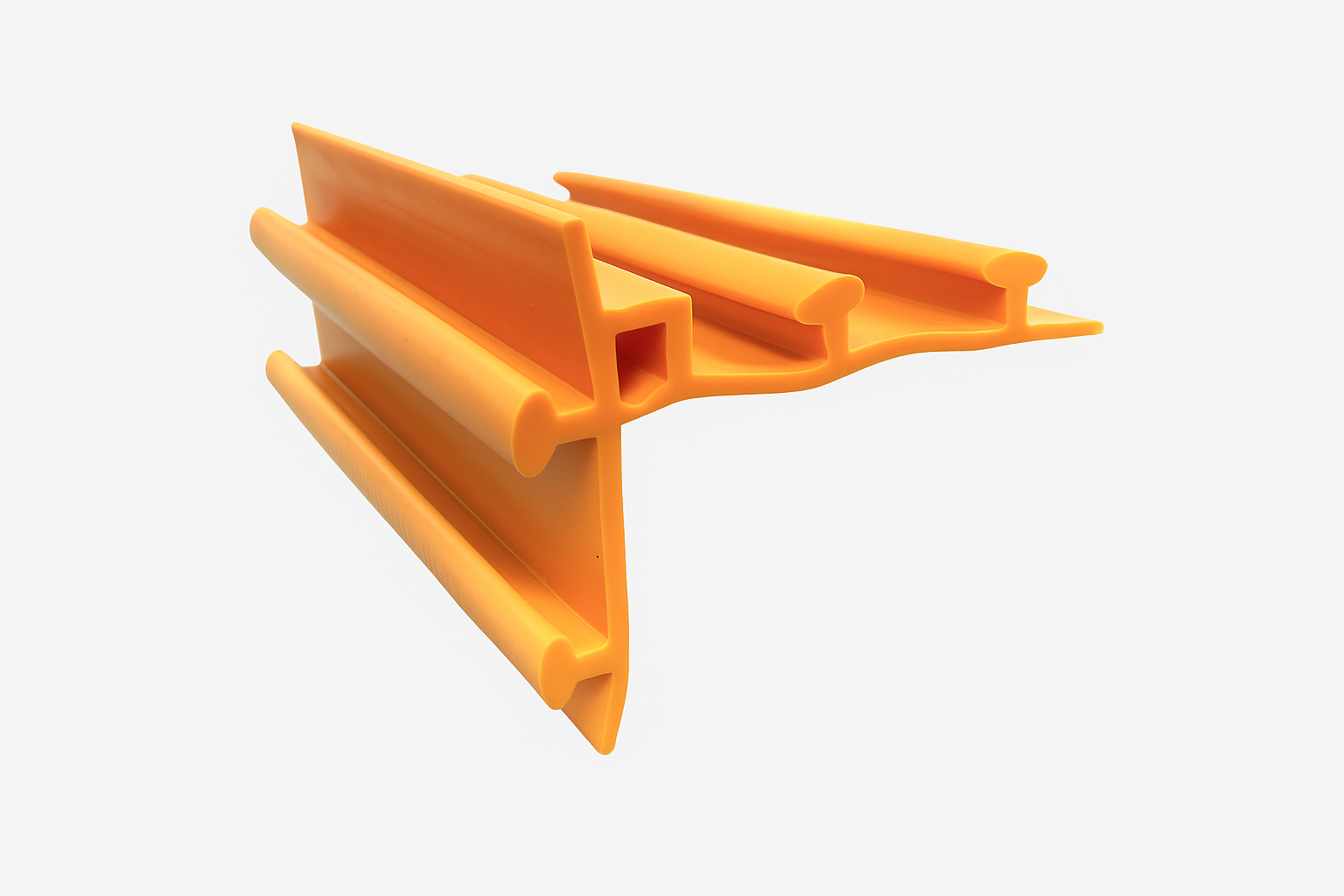

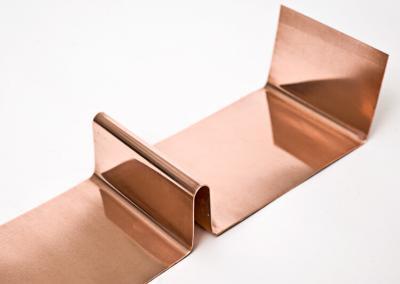

SURE-SHIELD® TPER Chemical Resistant Waterstop is extruded from specially compounded cross-linked TPER material that resists a wide range of chemicals, oils, fuels, solvents, alcohols and aqueous acids, bases and salt solutions.

SURE-SHIELD® TPER Chemical Resistant Waterstops provide high performance features for long-term durability and integrity of the structure, for continuous use in low and high temperatures and have excellent ozone and weather resistance.

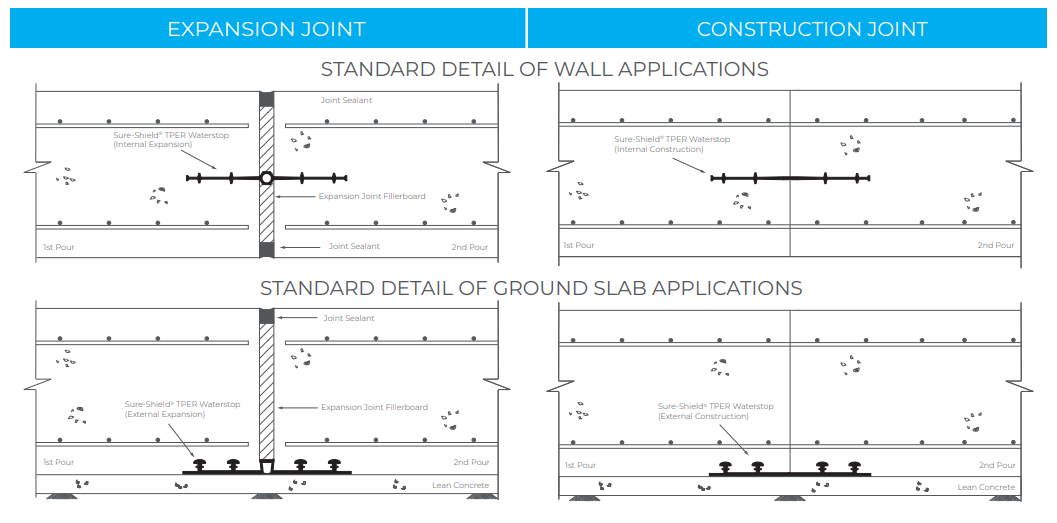

SURE-SHIELD® TPER Chemical Resistant Waterstop are designed for use in many types of applications and structures, and are available in a number of different size profiles that are for use in construction, contraction or expansion joints.

SURE-SHIELD® TPER Chemical Resistant Waterstops are heat weldable and allow for fast and easy on-site welding/joining of the waterstop.

The efficiency of any waterstop is very dependant upon good workmanship, installation, and on full compaction of the surrounding concrete around the waterstop during concrete placement. Optimum performance will be achieved if the waterstop is installed by keeping these important factors in mind.

Advantages

- A full range of profiles and sizes to suit all construction requirements.

- High quality compounded TPER for long term durability and integrity.

- Excellent heat & ozone resistance.

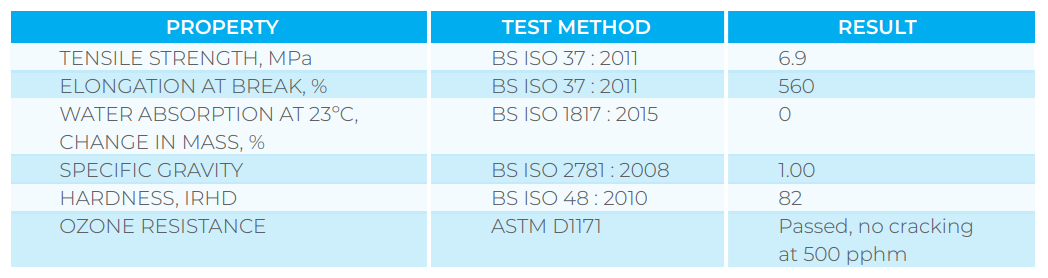

- Internal profiles come with factory pre-punched eyelets for easy and secure wire tying to reinforcement.

- Ability to withstand high hydrostatic head pressures.

- Factory made intersections to simplify and minimise on-site fabrication.

- On-site welding equipment is available upon request

Areas of Application

- Petrochemical Plants

- Chemical Plants

- Fuel Storage Containment

- Refineries

- Pulp & Paper Mills

- Train & Vehicular Tunnels

- Desalination Plants

- Reservoirs & Dams

- Swimming Pools

- Pharmaceutical Plants

- Waste Water Treatment Plants

- Sewage Treatment Plants

- Airports & Seaports

- Bridges & Highway

Note : The product’s design and performance, its intended use, installation and final confirmation and approval for use, must be provided by the project’s Design Engineer and Project Manager.

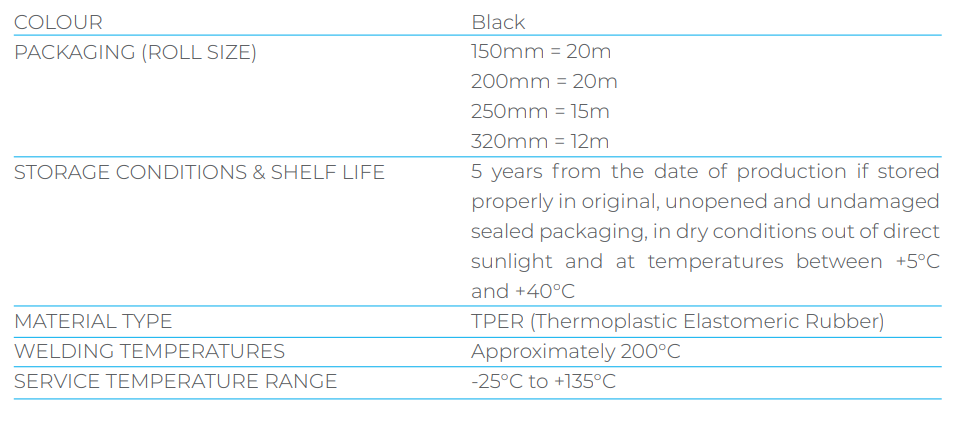

Physical Properties

Note: Refer to CORKJOINT®’s in house Certificate of Analysis (COA) dated 30/12/2016 for test results pertaining to the above. A COA is conducted on every batch of raw material that is used in the production of Sure-Shield® TPER waterstops. Independent laboratory test results are also available upon request. Project specific material properties can be custom compounded to suit. Material properties can vary between batches.

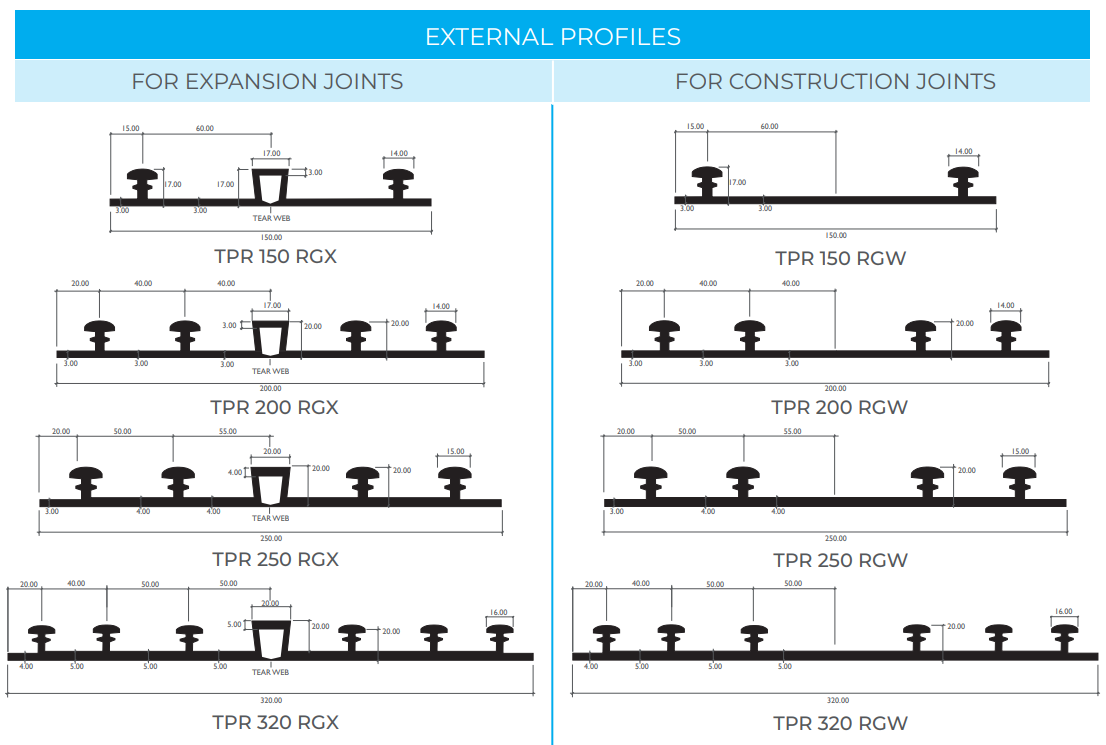

Profile Drawings

Profile Width Guidelines

The width of waterstop depends upon the thickness of the concrete and positioning of the reinforcement. The thickness of the concrete should be greater than or equal to the width of the waterstop profile. Refer to your engineer for further clarification and approval.

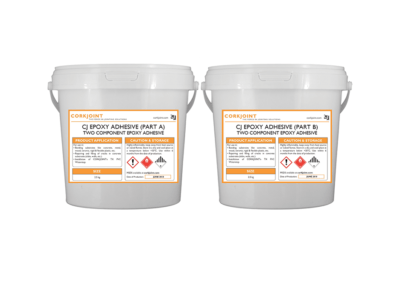

Site Jointing

CORKJOINT® recommends the use of its specialised welding equipment for on-site welding which consists of thermostatically-controlled Welding Irons and special Welding Jigs (each type of CORKJOINT® Sure-Shield® TPER Waterstop requires its own welding jig to suit the particular shape). On-site joining is a simple exercise using CORKJOINT® Heat Welding Equipment comprising of an adjustable Welding Jig and Welding Iron.

The ends of the waterstop are cut square and placed into the adjustable Welding Jig, then push the ends of the waterstop against the Welding Iron and bring the two ends together until the molten ends of the Sure-Shield® TPER Waterstop fuse together. When ordering Welding Equipment, please advise profile number of the waterstop required.

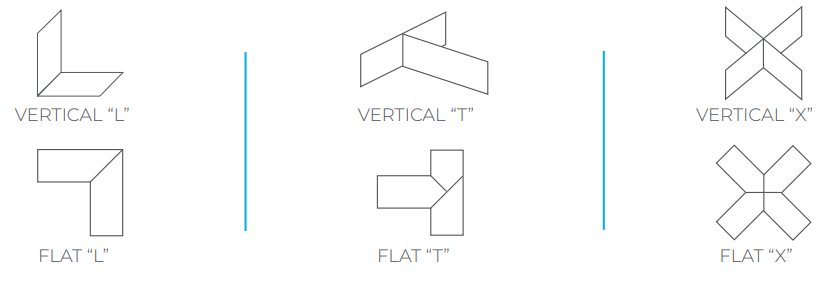

Factory Made Intersections

Written Specification

Where shown on the drawings waterstops shall be Sure-Shield® TPER Chemical Resistant Waterstop (state profile number required) as supplied by CORKJOINT®. Provide factory made waterstop fabrications for all changes of direction, intersections and transitions, leaving only straight butt joined splices for on-site fabrication.

Health and Safety Information

Joining of TX PVC Waterstops is performed by heat welding which results in the discharge of hydrogen chloride mist and vapour. In confined spaces or in still air conditions, the use of a ventilation fan or suitable respirator should be used, and the advice and approval of the site Safety Supervisor is essential. For further information or advice on health and safety precautions, safe handling, storage and correct disposal of products, please refer to the most recent product Safety Data Sheet (SDS) which is available upon request.

Disclaimer

The information and the recommendations relating to the application and end use of this product are given in good faith and are based on the information provided by the manufacturer of the product and/or the Company’s current knowledge and experience in connection with the product when properly stored, handled and applied under normal conditions and no liability of final function at the job site is assumed. In practice, the differences in materials, substrates and actual site conditions are such that no warranty in respect of merchantability of, or fitness for, particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written and/or oral recommendations, or from any other advice offered by the Company. The Company also has no express or implied knowledge of any particular purpose for which the product is required and any such information given will not be taken into account in the supply of this product. No responsibility or liability by the Company will be accepted for misuse, misreading or derivation from recommended guidelines in respect of this product and the user shall determine the suitability of the product for his intended use and assume all risks and liability in connection therewith. The information contained in our brochure may change at any time without notice. Any use of this product, Sure-Shield® TPER Waterstops, in any application should be approved as suitable for use/application by the Design Engineer and Project Manager.