SURE-STOP® LX PVC WATERSTOP

STANDARD PERFORMANCE SPECIFICATION (SPS) GRADE

PRODUCT BROCHURE

Press X Arrow Toggle for Full Screen View

Product Description

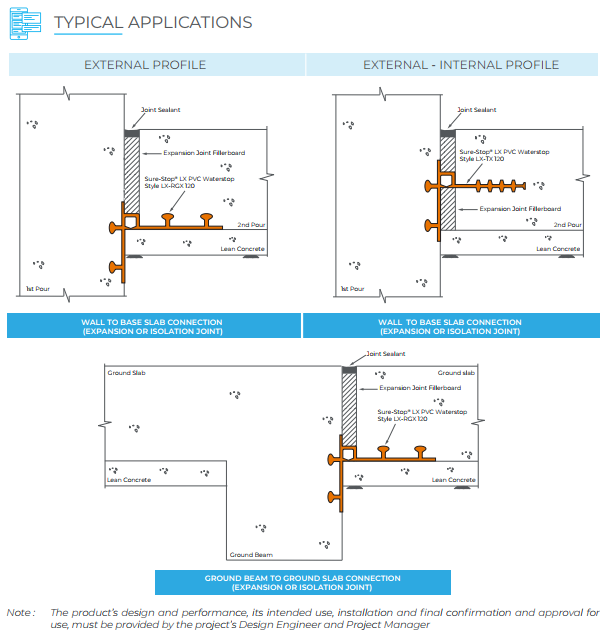

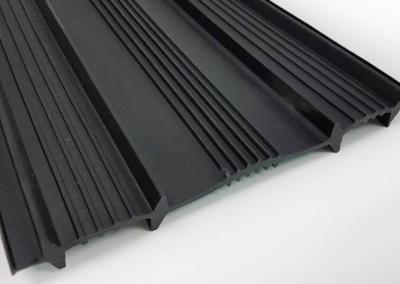

CORKJOINT® Sure-Stop® LX PVC Waterstop is a specially designed waterstop profile for use in construction joints, expansion joints, or isolation joints in concrete structures where traditional waterstop systems are not able to be installed, which can be specific locations for ground beams to ground slabs, below ground walls to ground slabs, or walls and/or beams to suspended slabs.

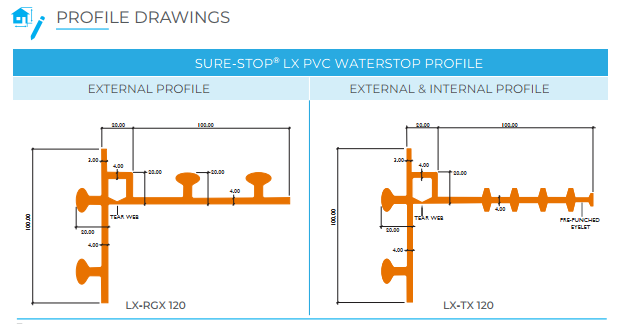

CORKJOINT® Sure-Stop® LX PVC Waterstop is available in two different profile types. Profile type LX-RGX 120 is designed where both waterstop legs are positioned and cast externally into each concrete section, and profile type LX-TX 120 where one waterstop leg is positioned and cast externally, and the other internally. Refer to the ‘Typical Applications’ and ‘Profile Drawings’ section for further information.

Advantages

- Ability to waterstop the joint where traditional PVC waterstop profiles or other waterstop systems cannot be installed.

- Able to accommodate longitudinal, lateral and differential movements in an expansion or isolation joint of a structure, due to its innovative design..

- A high performance material produced from virgin PVC compound (refer to material specification) giving long-term integrity and durability over time.

- Waterstops the joint and allows the joint to expand and contract freely from movements caused by thermal fluctuations, from serviceability loads from within the structure, and from ground settlement

- Factory produced intersection pieces are available for internal and external corner locations, and for areas where integration of traditional waterstop systems (external or internal profile types) are used in

construction joints or expansion joints, that run perpendicular into the joint of where the Sure-Stop® LX PVC Waterstop is placed. Refer to CORKJOINT® for further information on this.

Areas of Application

.For use in construction joints, expansion joints, or isolation joints in concrete structures where traditional waterstop systems cannot be installed.

- Ground beam to ground slab

- Beam to suspended slab

- Below ground wall to ground slab

- Wall to suspended slab.

Refer to ‘Typical Applications’ section in the Product Brochure..

Note : The product’s design and performance, its intended use, installation and final confirmation and approval for use, must be provided by the project’s Design Engineer and Project Manager.

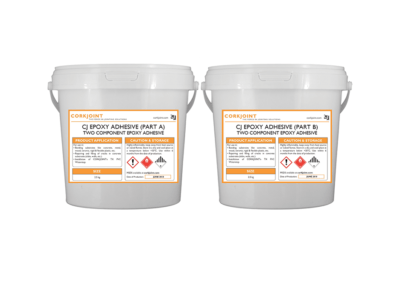

Site Joining & Welding Equipment

CORKJOINT® recommends the use of its specialised PVC waterstop Welding Equipment for on-site joining/welding of their Sure-Stop® LX PVC Waterstops, which consists of Teflon coated (non-stick), thermostatically heat-controlled Welding Irons and special Welding Jigs (each type of CORKJOINT® Sure-Stop® LX PVC Waterstop requires its own welding jig to suit the particular profile shape). On-site joining/welding is a simple exercise using CORKJOINT®’s specialised and professional Sure-Stop® LX PVC Waterstop Welding Equipment. The ends of the waterstop are cut square and placed into the adjustable Welding Jig, then push the ends of the waterstop against the Welding Iron and once sufficient melt on each end of the PVC waterstop has been achieved, remove the Welding Iron from the Welding Jig, and while the PVC waterstop is still clamped inside the Welding Jig, immediately bring the two melted ends together, until the molten PVC has fused together. When ordering CORKJOINT®’s Sure-Stop® LX PVC Waterstop Welding Equipment, please advise profile type of the waterstop required to be joined/welded. Refer to CORKJOINT® for their full site joining/welding guidelines.

Note: Corkjoint®’s Sure-Stop® PVC Waterstop Welding Iron L is to be used for Sure-Stop® LX PVC Waterstop Profile types.

Design Parameters

1. Sure-Stop® LX PVC Waterstop should only be installed into an expansion or isolation joint based upon the following:

- with a maximum joint width of 40mm for the LX-RGX 120 profile and the LX-TX 120 profile.

- with a maximum joint movement of 50mm (longitudinally and vertically) for the LX-RGX 120 profile and the LX-TX 120 profile

Note: If a wider joint or wider range of movement is required, please consult CORKJOINT.

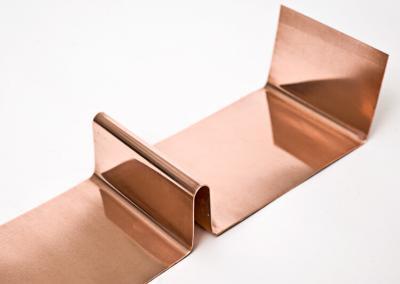

2. Factory produced intersection pieces must be used for internal and external corner locations, and also for areas where integration of traditional waterstop systems (external or internal profile types) are to be used in construction joints or expansion joints, or if hydrophilic (swellable) waterstops are to be used in construction joints, that run perpendicular into the joint of where the Sure-Stop® LX PVC Waterstop is placed. Refer to Corkjoint for further information on this.

Typical Installation Procedures

1. Sure-Stop® LX PVC Waterstop must be installed by skilled installers and must be in accordance with CORKJOINT®‘s recommended installation procedures (refer to our “Installation Method Guideline”) or to the design engineer’s installation specification requirements.

2. The concrete should be fully vibrated around the Sure-Stop® LX PVC Waterstop to help achieve ultimate sealing capabilities and full integration of the waterstop into the concrete of the structure.

3. Joining of Sure-Stop® LX PVC Waterstop should be performed by heat welding with special welding equipment provided by CORKJOINT® (refer to our job site joining/welding method guideline).

4. Factory produced intersection pieces must be used for internal and external corner locations, and also for areas where integration of traditional waterstop systems (external or internal profile types) are to be +used in construction joints or expansion joints, or if hydrophilic (swellable) waterstops are to be used in construction joints, that run perpendicular into the joint of where the Sure-Stop® LX PVC Waterstop is placed. Refer to CORKJOINT® for further information on this.

Note: The product’s design and performance, its intended use, installation and final confirmation and approval for use, must be provided by the project’s Design Engineer and Project Manager.

Written Specification

Waterstop shall be Sure-Stop® LX PVC Waterstop (state profile type) as supplied by CORKJOINT® with dimensions, shape and material properties as illustrated/mentioned in their product brochure. All installation and joining procedures must be according to CORKJOINT®’s recommendations and requirements, and also approved by the project’s Design Engineer.

Health and Safety Information

Joining of SURE-STOP® LX PVC Waterstop is performed by heat welding which results in the discharge of hydrogen chloride mist and vapour. In confined spaces or in still air conditions, the use of a ventilation fan or suitable respirator should be used, and the advice and approval of the site Safety Supervisor is essential. For further information or advice on health and safety precautions, safe handling, storage and correct disposal of products, please refer to the most recent product Safety Data Sheet (SDS) which is available upon request.

Product Brochure Validity

CORKJOINT® undertakes modifications to its product brochures on a continual basis, as and when required. Please check under the product summary section at www.corkjoint.com to ensure that you have the latest version of our product brochures.

Disclaimer

The information and the recommendations relating to the application and end use of this product are given in good faith and are based on the information provided by the manufacturer of the product and/or the Company’s current knowledge and experience in connection with the product when properly stored, handled and applied under normal conditions and no liability of final function at the job site is assumed. In practice, the differences in materials, substrates and actual site conditions are such that no warranty in respect of merchantability of, or fitness for, particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written and/or oral recommendations, or from any other advice offered by the Company. The Company also has no express or implied knowledge of any particular purpose for which the product is required and any such information given will not be taken into account in the supply of this product. No responsibility or liability by the Company will be accepted for misuse, misreading or derivation from recommended guidelines in respect of this product and the user shall determine the suitability of the product for his intended use and assume all risks and liability in connection therewith. The information contained in our brochure may change at any time without notice. Any use of this product, SURE-STOP® LX PVC Waterstops, in any application should be approved as suitable for use/application by the Design Engineer and Project Manager.