Joint Sealants & Joint Seals

CORKJOINT® is a specialist in the development, manufacture and supply of Joint Sealants and Joint Seals

Joint sealants and joint seals, are materials used to fill and seal gaps or joints between two or more surfaces in construction projects. They are applied to prevent air, water, and other elements from penetrating into a building or structure through these gaps.

CORKJOINT® has many different types of Joint Sealants and Joint Seals available for use, and depending upon the type of joint designed, the type of structure and the type of exposure that they could be subject to, determines the type to be used.

Click on the images below to view the product details. If you can’t find what you’re looking for on our website, ask, and we will source it for you.

Some common areas where joint sealants are used include:

1. Exterior and interior walls: Sealants are used to seal the gaps between wall panels, windows, doors, and other building components to prevent water, air, and insects from entering the building.

2. Concrete structures: Joint sealants are used to seal the gaps between concrete slabs or to fill cracks in concrete surfaces, preventing water from seeping through and causing damage.

3. Roofs: Sealants are applied to the joints between roofing materials, such as shingles or tiles, to prevent water leaks and increase the roof’s durability.

4. Flooring: Joint sealants are used to fill gaps between tiles, wood planks, or other flooring materials, creating a smooth and even surface.

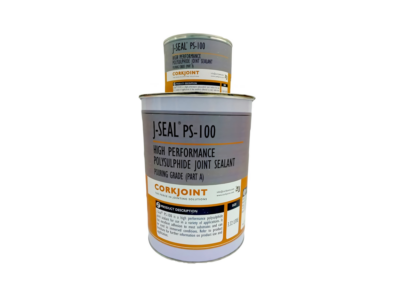

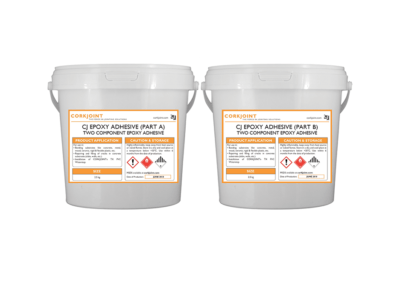

Types of Joint Sealants: There are several types of joint sealants available in the market, each with its own unique properties and applications. Some of the commonly used joint sealants include silicone, polyurethane, acrylic, polysulfide, and butyl rubber sealants.

Properties of Joint Sealants: Joint sealants are selected based on the specific requirements of the construction project. Some important properties to consider include adhesion, flexibility, durability, chemical resistance, and UV resistance.

Application Methods: Joint sealants can be applied using a variety of methods, including caulking, spraying, and troweling. The choice of application method depends on the type of sealant, the size of the joint, and the surface conditions.

Maintenance: Joint sealants require regular maintenance and inspection to ensure their effectiveness. Any signs of cracking, peeling, or deterioration should be addressed immediately to prevent water and air infiltration.

Safety Considerations: Joint sealants can emit volatile organic compounds (VOCs) during installation, which can be harmful to human health. It is important to follow proper safety protocols and use protective equipment, such as gloves and respirators, during installation.

Compatibility: It is important to choose joint seals that are compatible with the materials they are being applied to. For example, a sealant that is designed for use on concrete may not work as well on a metal surface. Compatibility also ensures that the sealant will not react negatively with other building materials or chemicals.

Durability: Joint seals must be durable and long-lasting to provide effective protection against water and air infiltration. They are typically rated based on their lifespan, with some sealants lasting 10-20 years or more.

Cost: The cost of joint seals varies depending on the type of sealant and the size of the project. While some sealants may be more expensive upfront, they may provide long-term savings by reducing the need for repairs or replacements.

In summary, joint sealants and joint seals are a critical component of building construction, providing protection against moisture and air infiltration, while accommodating for movement and temperature changes. The selection of the appropriate sealant depends on the specific requirements of the project, including compatibility, durability, and cost.